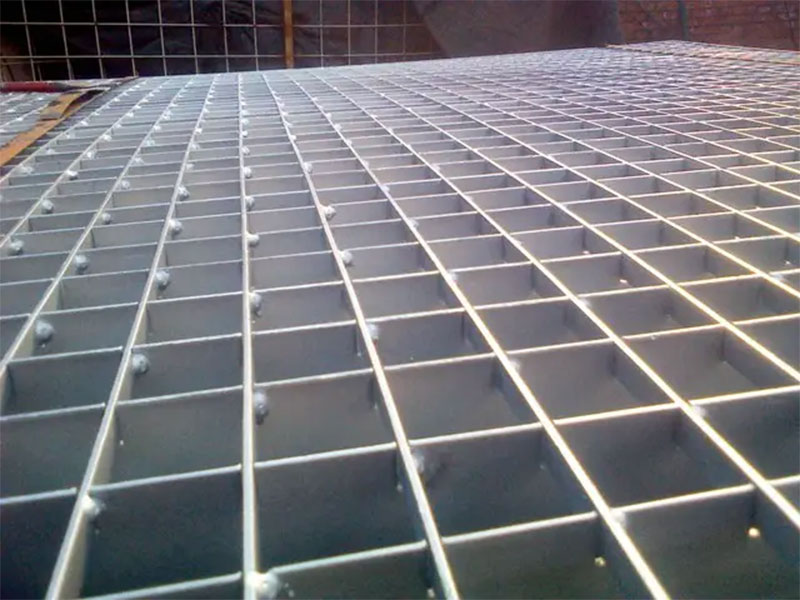

Steel grating is currently being used in various industries in various forms, such as steel structure platform slabs, trench covers, building drainage systems, steel ladder treads, building ceilings, etc. Due to the different needs of all walks of life, steel grating has gradually generated many different categories in the development process. According to the type, steel grating can be divided into plain type, serrated type and I type. According to surface treatment, steel grating is divided into: hot-dip galvanized steel grating, cold galvanized steel grating, painted steel grating, black sheet steel grating. According to the steel grating specifications, it is divided into: heavy steel grating, dense steel grating. There are more than 200 standard types. According to the needs of the use environment, different protective treatments can be applied to the surface of the steel grating, such as moisture-proof, durable Corrosion protection, etc. There are also many types if they are classified according to different function. Here are just a few examples. Ditch cover is a form of steel grating, which is mostly used in urban road administration and other projects, such as highways, parks, railways, airports, etc. Some civil buildings can also often use gutter made of steel grating cover plate. This kind of cover plate has beautiful appearance and simple lines, which can beautify the drainage system, and at the same time has a modern trendy atmosphere, which can enhance the overall appearance of the city. Ceiling steel grating is light, beautiful in appearance, and easy to install. When used as a suspended ceiling, the surface of the steel grating is often hot-dip galvanized, so that the suspended ceiling can have 30 years of anti-corrosion durability and paint-free maintenance. Ceiling steel gratings are widely used in various industrial and civil projects that require building ceilings. Each industry has different demand for steel grating products, and the difference is relatively large.

Post time: Oct-10-2022