OEM/ODM Supplier Serrated Carbon Steel Bar Grating - I Shape Plain And Serrated Steel Grating – Chengsen

OEM/ODM Supplier Serrated Carbon Steel Bar Grating - I Shape Plain And Serrated Steel Grating – Chengsen Detail:

I Type Steel Plate Surface Treatment

Hot galvanizing, cold galvanizing, painting, dipping rust oil, no treatment (general stainless steel without treatment).

I Type Steel Plate Production Method

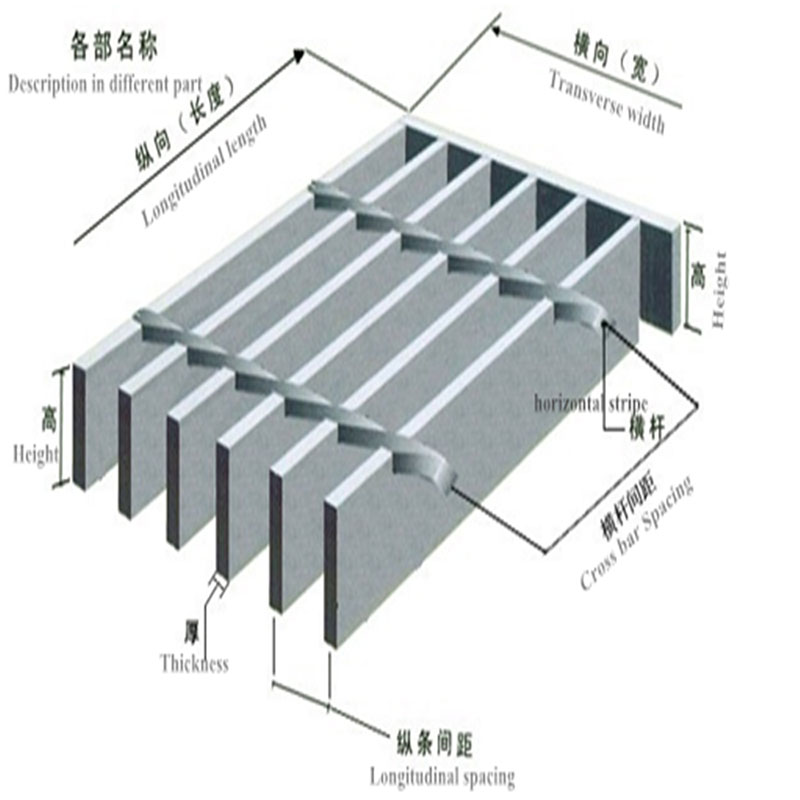

I type steel plate is composed of load flat steel and horizontal bar arranged according to a certain spacing of longitude and latitude, using 200 tons of hydraulic resistance welding automation equipment welding into the original plate, after cutting, opening, rimming and other processes processed into customer requirements.

Steel Grating I Type, Bearing Bars At 30mm Pitch

|

Type |

Beam |

Flange |

Abdominal |

Flange |

Theory |

Load |

ClearSpan |

||||||||||||||

|

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|||||||

|

G757/30/50I |

75 |

7 |

4 |

12 |

126.1 |

U |

6460 |

1615 |

717 |

403 |

258 |

179 |

131 |

100 |

79 |

64 |

53 |

44 |

38 |

32 |

28 |

|

G757/30/100 I |

120.7 |

D |

0.09 |

0.37 |

0.83 |

1.47 |

2.3 |

3.31 |

4.5 |

5.88 |

7.47 |

9.25 |

11.26 |

13.3 |

15.89 |

18.11 |

20.99 |

||||

|

G657/30/50I |

65 |

7 |

4 |

10 |

110.1 |

U |

4862 |

1215 |

540 |

303 |

194 |

135 |

99 |

75 |

60 |

48 |

40 |

33 |

28 |

24 |

21 |

|

G657/30/100I |

104.8 |

D |

0.11 |

0.42 |

0.95 |

1.69 |

2.65 |

3.83 |

5.22 |

6.77 |

8.71 |

10.67 |

13.07 |

15.36 |

18.05 |

20.94 |

24.29 |

||||

|

G607/30/50I |

60 |

7 |

4 |

10 |

99.1 |

U |

4216 |

1054 |

468 |

263 |

168 |

117 |

86 |

65 |

52 |

42 |

34 |

29 |

24 |

21 |

18 |

|

G607/30/100I |

96.1 |

D |

0.11 |

0.46 |

1.03 |

1.83 |

2.86 |

4.13 |

5.65 |

7.31 |

9.4 |

11.62 |

13.85 |

16.81 |

19.29 |

22.82 |

25.97 |

||||

|

G557/30/501 |

55 |

7 |

4 |

8.5 |

90.3 |

U |

3502 |

875 |

389 |

218 |

140 |

97 |

71 |

54 |

43 |

35 |

28 |

24 |

20 |

17 |

|

|

G557/30/100I |

87.3 |

D |

0.13 |

0.5 |

1.13 |

2 |

3.15 |

4.53 |

6.17 |

8.03 |

10.29 |

12.82 |

15.11 |

18.44 |

21.32 |

24.55 |

|||||

|

G507/30/50I |

50 |

7 |

4 |

8 |

83.2 |

U |

2912 |

728 |

323 |

182 |

116 |

80 |

59 |

45 |

35 |

29 |

24 |

20 |

17 |

||

|

G507/30/100I |

80.2 |

D |

0.14 |

0.55 |

1.24 |

2.21 |

3.44 |

4.94 |

6.78 |

8.85 |

11.09 |

14.09 |

17.14 |

20.37 |

24.01 |

||||||

|

G505/30/50I |

50 |

5 |

3 |

8.5 |

62.8 |

U |

2085 |

521 |

231 |

130 |

83 |

57 |

42 |

32 |

25 |

20 |

17 |

14 |

|||

|

G505/30/100I |

59.8 |

D |

0.14 |

0.55 |

1.23 |

2.2 |

3.44 |

4.91 |

6.73 |

8.79 |

11.06 |

13.57 |

16.97 |

19.95 |

|||||||

|

G445/30/50I |

44 |

5 |

3 |

8 |

56.5 |

U |

1654 |

413 |

183 |

103 |

66 |

45 |

33 |

25 |

20 |

16 |

13 |

||||

|

G445/30/100I |

53.5 |

D |

0.16 |

0.62 |

1.4 |

2.5 |

3.92 |

5.56 |

7.59 |

9.86 |

12.71 |

15.6 |

18.7 |

||||||||

|

G385/30/50I |

38 |

5 |

3 |

7 |

49.9 |

U |

1246 |

311 |

138 |

77 |

49 |

34 |

25 |

19 |

15 |

12 |

|||||

|

G385/30/100I |

46.9 |

D |

0.18 |

0.73 |

1.64 |

2.89 |

4.51 |

6.52 |

8.93 |

11.64 |

14.82 |

18.22 |

|||||||||

|

G325/30/50I |

32 |

5 |

3 |

6 |

43.3 |

U |

884 |

221 |

98 |

55 |

35 |

24 |

18 |

13 |

10 |

||||||

|

G325/30/100I |

40.3 |

D |

0.21 |

0.86 |

1.94 |

3.44 |

5.37 |

7.68 |

10.74 |

13.35 |

16.6 |

||||||||||

|

G255/30/50I |

25 |

5 |

3 |

4.5 |

35.1 |

U |

544 |

136 |

60 |

34 |

21 |

15 |

11 |

||||||||

|

G255/30/100I |

32.1 |

D |

0.28 |

1.1 |

2.47 |

4.45 |

6.75 |

10.06 |

13.77 |

||||||||||||

1. The even load walkway plate for a single person should be over 3.0KN/m2.

2. The even load walkway plate for a double-direction should be over 5.0KN/m2.

3. The even load walkway plate for many people should be over 7.5KN/m2.

Steel Grating I Style Bearing Bars At 40mm Pitch

|

Type |

Beam |

Flange |

Abdominal |

Flange |

Theory |

Load |

ClearSpan |

||||||||||||||

|

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|||||||

|

G6757/40/50 I |

75 |

7 |

4 |

12 |

101 |

U |

4845 |

1211 |

538 |

302 |

193 |

134 |

98 |

75 |

75 |

59 |

48 |

40 |

33 |

28 |

24 |

|

G757/40/100 I |

95.6 |

D |

0.09 |

0.37 |

0.83 |

1.47 |

2.29 |

3.31 |

4.49 |

5.89 |

5.89 |

7.44 |

9.27 |

11.35 |

13.33 |

15.66. |

18.16 |

||||

|

G657/40/50 I |

65 |

7 |

4 |

10 |

88.5 |

U |

3646 |

911 |

405 |

227 |

145 |

101 |

74 |

56 |

56 |

45 |

36 |

30 |

25 |

21 |

18 |

|

G657/40/100 I |

83.2 |

D |

0.11 |

0.42 |

0.95 |

1.69 |

2.64 |

3.83 |

5.21 |

6.75 |

6.75 |

8.72 |

10.68 |

13.1 |

15.54 |

18.1 |

21 |

||||

|

G607/40/50 I |

60 |

7 |

4 |

10 |

78.9 |

U |

3162 |

790 |

351 |

197 |

126 |

87 |

64 |

49 |

49 |

39 |

31 |

26 |

21 |

18 |

16 |

|

G607740/100 I |

75.9 |

D |

0.11 |

0.46 |

1.03 |

1.83 |

2.86 |

4.1 |

5.61 |

7.35 |

7.35 |

9.41 |

11.46 |

14.13 |

16.28 |

19.33 |

23.23 |

||||

|

G557/40/50 I |

55 |

7 |

4 |

8.5 |

71.9 |

U |

2626 |

656 |

291 |

164 |

105 |

72 |

53 |

41 |

41 |

32 |

26 |

21 |

18 |

15 |

|

|

G557/40/100 I |

68.9 |

D |

0.13 |

0.5 |

1.13 |

2.01 |

3.15 |

4.49 |

6.14 |

8.14 |

8.14 |

10.22 |

12.72 |

15.14 |

18.48 |

21.37 |

|||||

|

G507/40/50 I |

50 |

7 |

4 |

8 |

66.9 |

U |

2184 |

546 |

242 |

136 |

87 |

60 |

44 |

34 |

34 |

26 |

21 |

18 |

15 |

||

|

G507/40/100 I |

63.9 |

D |

0.14 |

0.55 |

1.24 |

2.2 |

3.45 |

4.95 |

6.74 |

8.93 |

8.93 |

11 |

13.62 |

17.18 |

20.42 |

||||||

|

G505/40/50 I |

50 |

5 |

3 |

8.5 |

50.4 |

U |

1564 |

391 |

173 |

97 |

62 |

43 |

31 |

24 |

24 |

19 |

15 |

12 |

|||

|

G50540/100 I |

47.4 |

D |

0.14 |

0.55 |

1.23 |

2.19 |

3.43 |

4.95 |

6.64 |

8.8 |

8.8 |

11.22 |

13.6 |

16.05 |

|||||||

|

G445/40/50I |

44 |

5 |

3 |

8 |

45.5 |

U |

1241 |

310 |

137 |

77 |

49 |

34 |

25 |

19 |

19 |

15 |

12 |

||||

|

G445/40/100I |

42.5 |

D |

0.16 |

0.62 |

1.4 |

2.49 |

3.88 |

5.61 |

7.68 |

10.01 |

10.01 |

12.73 |

15.64 |

||||||||

|

G385/40/50I |

38 |

5 |

3 |

7 |

40.3 |

U |

935 |

233 |

103 |

58 |

37 |

25 |

19 |

14 |

14 |

11 |

|||||

|

G38540/1001 |

37.3 |

D |

0.18 |

0.73 |

1.63 |

2.91 |

4.55 |

64 |

9.06 |

11.47 |

11.47 |

14.54 |

|||||||||

|

G325/40/50I |

32 |

5 |

3 |

6 |

35.1 |

U |

663 |

165 |

73 |

41 |

26 |

18 |

13 |

10 |

10 |

||||||

|

G325/40/100I |

32.1 |

D |

0.21 |

0.86 |

1.92 |

3.43 |

5.33 |

7.69 |

10.37 |

13.71 |

13.71 |

||||||||||

|

G255/40/50I |

25 |

5 |

3 |

4.5 |

28.7 |

U |

408 |

102 |

45 |

25 |

16 |

11 |

8 |

||||||||

|

G255/40/100 I |

25.8 |

D |

0.28 |

1.1 |

2.47 |

4.36 |

6.86 |

9.86 |

13.41 |

||||||||||||

Notes:

1. U: safe and uniformly distributed load, KN/m2.

2. D: the maximum deflection corresponding to the listed safe load.

3. Theoretical weight is the weight of 1m length of hot dipped galvanized grating.

Product detail pictures:

Related Product Guide:

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of quality first, customer supreme for OEM/ODM Supplier Serrated Carbon Steel Bar Grating - I Shape Plain And Serrated Steel Grating – Chengsen , The product will supply to all over the world, such as: Niger, Nicaragua, Comoros, We strive for excellence, constant improvement and innovation, is committed to make us the customer trust and the first choice of engineering machinery accessories brand suppliers. Choose us, sharing a win-win situation!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.