PriceList for Grating Galvanized Steel - Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads – Chengsen

PriceList for Grating Galvanized Steel - Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads – Chengsen Detail:

Description

Introduction to stair step grating:

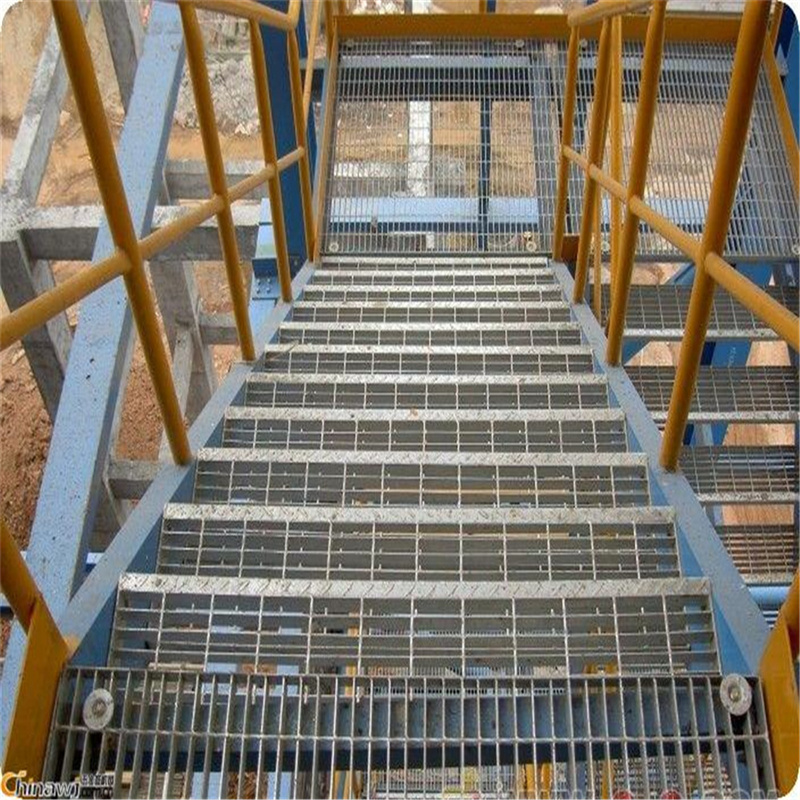

Stair STEP PLATE IS STEEL LATTICE PLATE PROCESSING AND BECOME (STEEL LATTICE PLATE IS TO USE FLAT STEEL TO UNDERTAKE CROSS ARRANGEMENT ACCORDING TO CERTAIN SPACING AND CROSSBAR, AND WELD A KIND OF STEEL PRODUCT THAT HAS SQUARE LATTICE IN THE MIDDLE), ALSO CALL STEEL GRATING STEP PLATE. The surface of the product is generally treated with hot dip galvanizing or electric galvanizing. Stair step plate is a branch of steel plate products, step plate is also known as stair step plate, steel ladder plate, steel ladder is used for steel structure platform of a steel plate, stair step plate is a steel structure industrial platform up and down the necessary products.

Staircase step plate model

Generally, the step board can be divided into: T1 step board, T2 step board, T3 step board, T4 step board. The main basis is a front guard plate and perforated side plate, can also be determined according to customer requirements.

How to select the appropriate step board can be selected by the following methods: This is mainly based on the function of the step board and the use of the environment to divide. If there are drawings, please strictly follow the design drawings of the engineering designer. If the flow of people up and down the stairs is much, the front guard board should be used, on the contrary, the front guard board can not be added to reduce your cost. When installing, it is fixed by screws or welding. The rear side plate that is fixed by bolts should be punched, and the side plate that is directly welded should not be thickened. Step plates should be manufactured according to the national steel ladder production standard. You can search “02J401″ atlas for reference, which has the corresponding steel ladder standard and the number and type of step plates equipped under the standard. Step plate generally uses hot dip zinc or spray paint surface treatment, spray paint to spray before spray paint, in order to achieve long-term anti-corrosion effect.

staircase step plate installation

Galvanized steel plate step plate is a kind of staircase used for platform steel plate, according to the installation method, there are generally welding fixed and bolt fixed two types. Directly welded to the keel steel beam, do not need to add step plate side plate, relatively more economic and durable but not easy to disassemble; The two sides of the step plate fixed with bolts need to be thickened. Drill holes in the side plate. The installation is directly fixed by bolts and can be reused repeatedly. Customers can be customized according to their actual needs, can be made of any type of steel panels made of various sizes, to match the corresponding staircase. But from the economic point of view, we recommend that we use our recommended size whenever possible.

Staircase step plate size specification

The step plate with different anti-slip front guard plate can be produced, and its size can be specified as needed.

① The width is 700mm,800mm,900mm, and the minimum width is 600mm. The width should not be greater than 1200mm. For a single person through the staircase, the width between the two inclined beams or guardrail should not be less than 600mm.

(2) When the staircase frequently bears several people crossing at the same time or is used as an evacuation route for personnel, the ladder width should be increased to 1200mm.

③ The edge of the staircase step plate should be able to bear the load of 1.5kN, when the width is not greater than 1200mm, the load on the area of 100mm×100mm; When the width is greater than 1200mm, add a load of 1.5kN at 600mm of each line, and the deflection of the stair pedal should not exceed 1/500 of the stair span.

⑤ The lap part of the vertical projection of the two adjacent stair step plates should not be less than 10mm.

Five: stair step board use

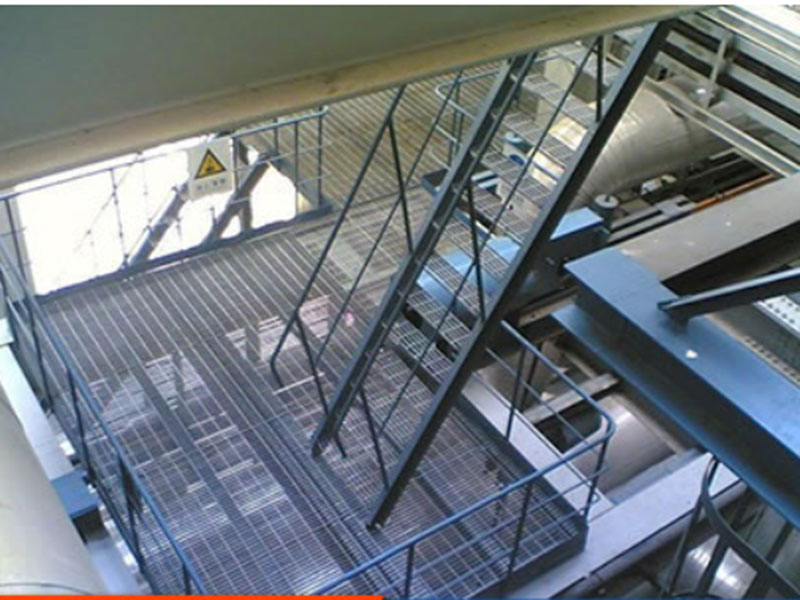

The use of tread board is very wide, in power plants, water plants and other factories, and municipal engineering, sanitation engineering and other fields of platform, corridor, theater, visiting platform, parking lot and other large places of ground platform, are widely used.

STEEL LADDER

Steel ladder are formation shaped with steel grating treads, 15J401 standard.

It is hot dipped galvanized, easy for installation and maintenance.

|

Type |

Model No. |

Gradient |

Width |

Stringer Type |

Tread |

|

Inclined ladder A |

T35.5A08 |

35.5° |

800 |

-200×10 |

G255/30/100 |

|

T35.5A10 |

35.5° |

1000 |

-200×10 |

G325/30/100 |

|

|

T45A06 |

45° |

600 |

-180×10 |

G255/30/100 |

|

|

T45A08 |

45° |

800 |

-180×10 |

G255/30/100 |

|

|

T45A10 |

45° |

1000 |

-180×10 |

G325/30/100 |

|

|

T59A06 |

59° |

600 |

-150×8 |

G255/30/100 |

|

|

T59A08 |

59° |

800 |

-150×8 |

G255/30/100 |

|

|

T73A06 |

73° |

1000 |

-120×8 |

G255/30/100 |

|

|

Inclined ladder B |

T35.5B08 |

35.5° |

800 |

C16a |

G255/30/100 |

|

T35.5B10 |

35.5° |

1000 |

C16a |

G325/30/100 |

|

|

T45B06 |

45° |

600 |

C16a |

G255/30/100 |

|

|

T45B08 |

45° |

800 |

C16a |

G255/30/100 |

|

|

T45B10 |

45° |

1000 |

C16a |

G325/30/100 |

|

|

T59B06 |

59° |

600 |

C16a |

G255/30/100 |

|

|

T59B08 |

59° |

800 |

C16a |

G255/30/100 |

|

|

T73B06 |

73° |

600 |

C12.6 |

G255/30/100 |

|

|

Inclined ladder D |

T35.5D08 |

35.5° |

800 |

C16a |

G255/30/100 |

|

T35.5D10 |

35.5° |

1000 |

C16a |

G325/30/100 |

|

|

T45D06 |

45° |

600 |

C16a |

G255/30/100 |

|

|

T45D08 |

45° |

800 |

C16a |

G255/30/100 |

|

|

T45D10 |

45° |

1000 |

C16a |

G325/30/100 |

|

|

T59D06 |

59° |

600 |

C16a |

G255/30/100 |

|

|

T59D08 |

59° |

800 |

C16a |

G255/30/100 |

|

|

T73D06 |

73° |

600 |

C12.6 |

G255/30/100 |

* Beam for Type A is made of steel plate, stringer for type B and type D

is made of channel steel, there is a platform on top of type D ladder.

* If the gradient is over 45 degree, the guardrail dolumn should be

vertically installed against the side beam.

* For more details, please take referrence from <steel ladder atlas 15J401>.

* Straight Ladder with or without protection cage are available.

Product detail pictures:

Related Product Guide:

Sticking for the belief of Creating items of top of the range and creating buddies with people today from all over the world, we normally put the interest of shoppers in the first place for PriceList for Grating Galvanized Steel - Hot Dip Galvanized Composite Steel Grating Grilles Stair Steps And Stair Treads – Chengsen , The product will supply to all over the world, such as: French, Peru, Armenia, The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.